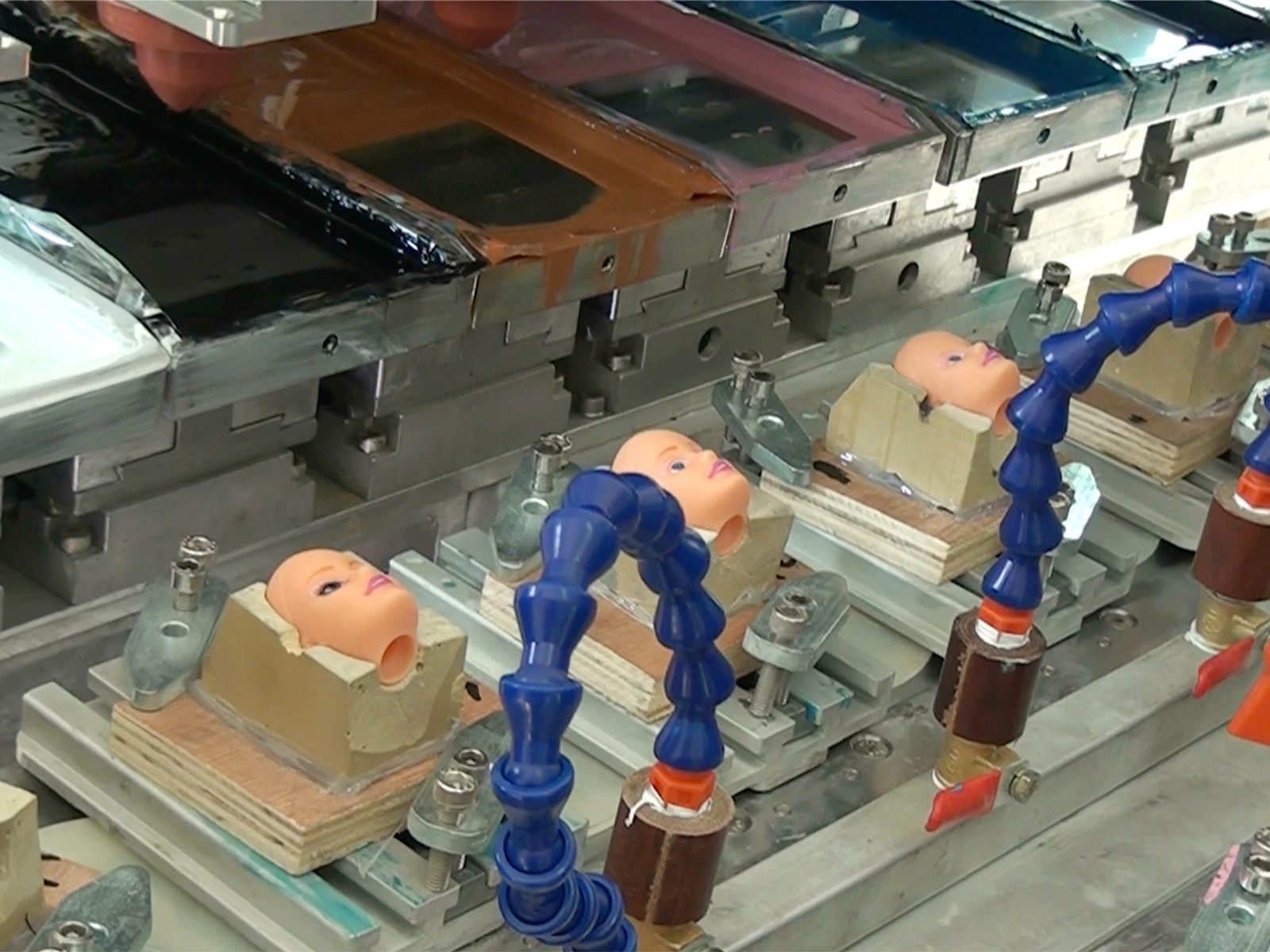

Some Painting Defects and Improvement in Custom Vinyl Figure

Painting is a critical step in customizing vinyl figures. It directly impacts the aesthetics and value of the finished product. Here are some common painting defects, and how to fix them. These methods can be applied to the production of custom vinyl figures.

Paint Bleeding

During the customization of vinyl figures, paint bleeding is common due to misaligned components or slight deformations. Unintentional paint spreading into adjacent areas is the result.

Improvements: Check and maintain your molds regularly to ensure that they are aligned. Consider precision masking for complex vinyl figures.

Paint Running

When custom painting vinyl figures, paint running can be caused by an excessive thickness of paint or incorrect drying settings.

Improvements: Improve consistency of custom vinyl figures by optimizing spraying parameters and implementing controlled drying cycles.

Paint Pooling

Paint pooling can occur in custom vinyl figures when excess paint is accumulated. This creates thick, visible spots.

Improvements: Adjust the spray gun's angle and distance. Apply multiple thin coats instead of a heavy one.

Oil Contamination

The oil stains can cause paint to adhere poorly, leading to fish-eye defects and poor finishes.

Improvements: Use oil-removing solvents and thorough cleaning procedures before painting vinyl figures.

Foreign Material Contamination

Custom vinyl figures can be damaged by dust or debris that settles on the wet paint.

Improvements: Maintain a paint room with proper air filtering during the process.

Inadequate coverage

Custom painting vinyl figures can require several layers of pigments, particularly when light colors are used over dark bases.

Improvements: Increase paint opacity by using a high-hiding primer.

Pinholes

Trapped air or moisture can cause small holes to appear on the surface of vinyl figures.

Improvement: Control humidity levels and improve substrate sealing.

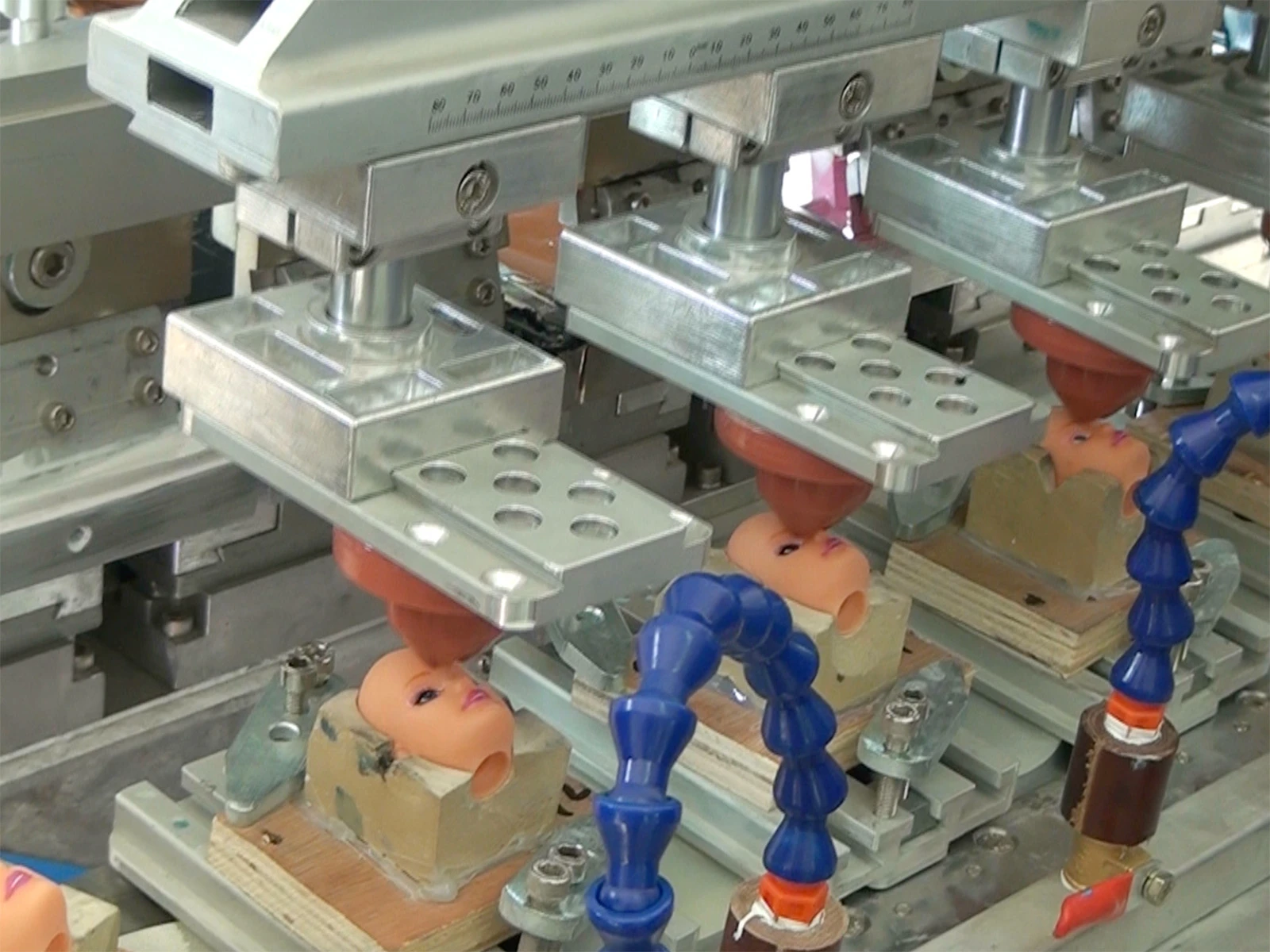

Misalignment

For complex designs, it is important to register multiple colors precisely. A misalignment of colors can ruin the intended effect.

Improvements: Use precision masking and secure positioning fixtures when painting in multiple stages.

Fuzzy Edges

The sharpness of custom vinyl figures can be diminished by poorly defined edges between colors.

Improvements: Use better quality masking material and ensure adhesion when applying.

Poor Adhesion

If you notice paint peeling off or flaking on the custom vinyl figures, it may be due to improper substrate preparation or an incompatible material.

Improvements: Conduct adhesion testing and apply proper surface treatments before full production.

Insufficient Hiding

Custom painting vinyl figures can be problematic, especially when using transparent pigments.

Improvements: Increase the paint coverage by optimizing the formula or applying an intermediate sealant layer.

Missed Areas

Complex custom vinyl figures that have intricate details can sometimes be incompletely covered in certain areas.

Improvements: Implement quality control at every stage of spraying. Develop systematic spraying procedure.

Surface Scratches

Custom vinyl figures can be damaged by handling damage before or after painting.

Improvements: Implement protective handling protocols, and ensure proper curing of goods before moving.

Color Inconsistency

Vinyl figures customization can be difficult to maintain color consistency across batches.

Improvements: Standardize color formulas, and implement strict quality controls.

Glossy Variation

Custom vinyl figures can appear uneven or patchy if they have an uneven gloss level.

Improvements: Control spraying uniformity, and implement consistent drying parameters.

Webbing

When vinyl figures are custom painted, paint filaments can form when masked areas are separated.

Improvements: Adjust mask removal technique and optimize paint viscosity.

Complete Drying

If the drying conditions for custom vinyl figures are not adequate, tackiness or soft paint can remain.

Improvements: Check curing parameters, and make sure proper ventilation is maintained throughout the process.